A research team from Xiamen University has experimentally demonstrated that using a hexagonal mesa structure can significantly improve the performance of indium gallium nitride (InGaN) microgreen light-emitting diodes (LEDs). The research, published in *Optics Express*, Volume 33, Page 42747, 2025, details how optimizing the geometry of the microLED mesa can solve current uniformity problems and improve photoelectronic efficiency—crucial for next-generation display and communication technologies. The "mesa" refers to the raised area on the microLED that forms the light-emitting surface (LES), the core component for light emission.

1. Research Design: Comparison of Three Mesa Structures and the Advantages of Hexagonal Structures

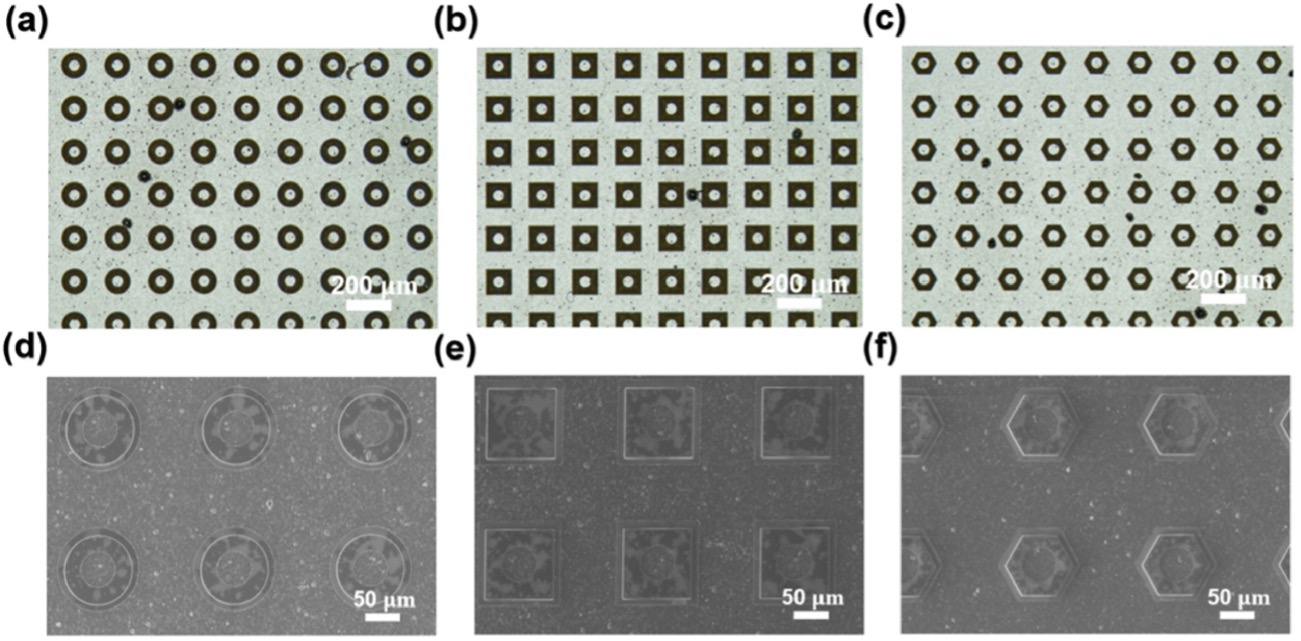

This study compared three mesa structures: circular, square, and hexagonal. All structures were fabricated from indium gallium nitride/gallium nitride (InGaN/GaN) multilayer materials grown on patterned sapphire substrates using metal-organic chemical vapor deposition (MOCVD).

The hexagonal mesa, with its six evenly distributed vertices, achieves three key optimizations:

* It shortens the maximum distance between the central p-electrode and the mesa edge, improving the uniformity of current diffusion within the active region;

* It alleviates the corner current accumulation problem commonly found in square mesas, reducing low-current-density regions that lead to performance degradation;

* It possesses a balanced perimeter-to-electrode area (P/A) ratio, optimizing carrier injection efficiency while suppressing parasitic recombination.

2. Application Value: Core Scenarios and Technological Significance of Miniature Green LEDs

Miniature green LEDs operating within the peak sensitivity range of the human eye are key devices in fields such as high-fidelity color displays, augmented reality/virtual reality (AR/VR) systems, phototherapy, and visible light communication.

The core value of this research lies in demonstrating that microscale structural geometry optimization can achieve quantifiable performance improvements without altering material composition. Hexagonal mesa, with its superior current spreading capability, lower non-radiative loss, and higher external quantum efficiency (EQE), has become a highly promising structural solution for high-efficiency micro-display and communication LEDs, aligning perfectly with the industry's trend towards miniaturized, high-brightness, and long-lifespan photonic devices.

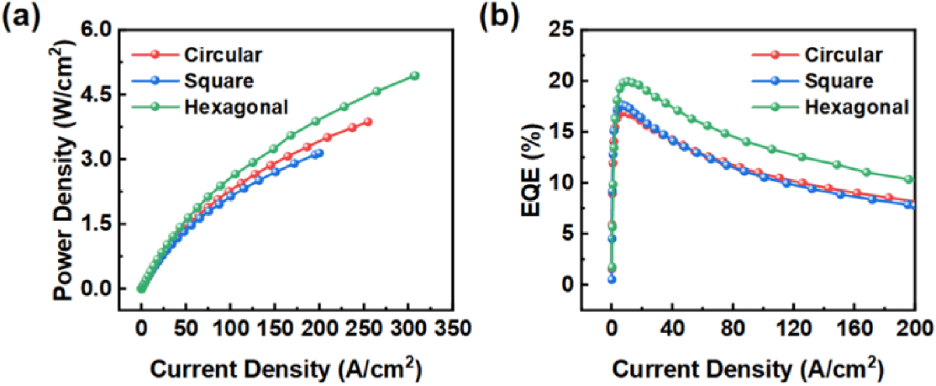

3. Experimental Data: Quantifying the Performance Advantages of Hexagonal Structures

In electrical performance testing, the turn-on voltage of the three structural devices remained consistent at around 3.3V, but significant differences were observed at high bias voltages:

At a bias voltage of 10V, the current density of the hexagonal LED reached 285.8A/cm², far exceeding that of the square (199.9A/cm²) and circular (164.7A/cm²) mesa; this data indicates that the optimized current spreading effect directly improves carrier injection efficiency.

As the current increases, the emission wavelength of the hexagonal LED exhibits a significant blue shift of 2.9nm, meaning that the more uniform carrier distribution reduces the quantum confinement effect.

In optical performance testing, the advantages of the hexagonal structure became even more apparent:

At an injection current density of 200 A/cm², the output power density of the hexagonal micro-LED reached 4.94 W/cm², exceeding that of circular (3.86 W/cm²) and square (3.14 W/cm²) structures;

Its external quantum efficiency (EQE) peaked at 19.9% at a current density of 10.41 A/cm², superior to that of circular (16.9%) and square (17.6%) devices;

As a key indicator of efficiency degradation with current, the EQE decay rate of the hexagonal structure was only 48.2%, lower than that of circular (52.4%) and square (56.1%) structures, demonstrating its superior performance in thermal balance and electron-hole recombination balance.