Ever wondered how crystal chandeliers are made? These stunning crystal chandeliers require the combined efforts of a village. From the initial conception to the design drawings, through the manufacturing process, and finally to the finished product, each step is crucial and requires exceptional skill. In this article, we'll take a deep dive into the crystal chandelier manufacturing process.

Step 1: Design

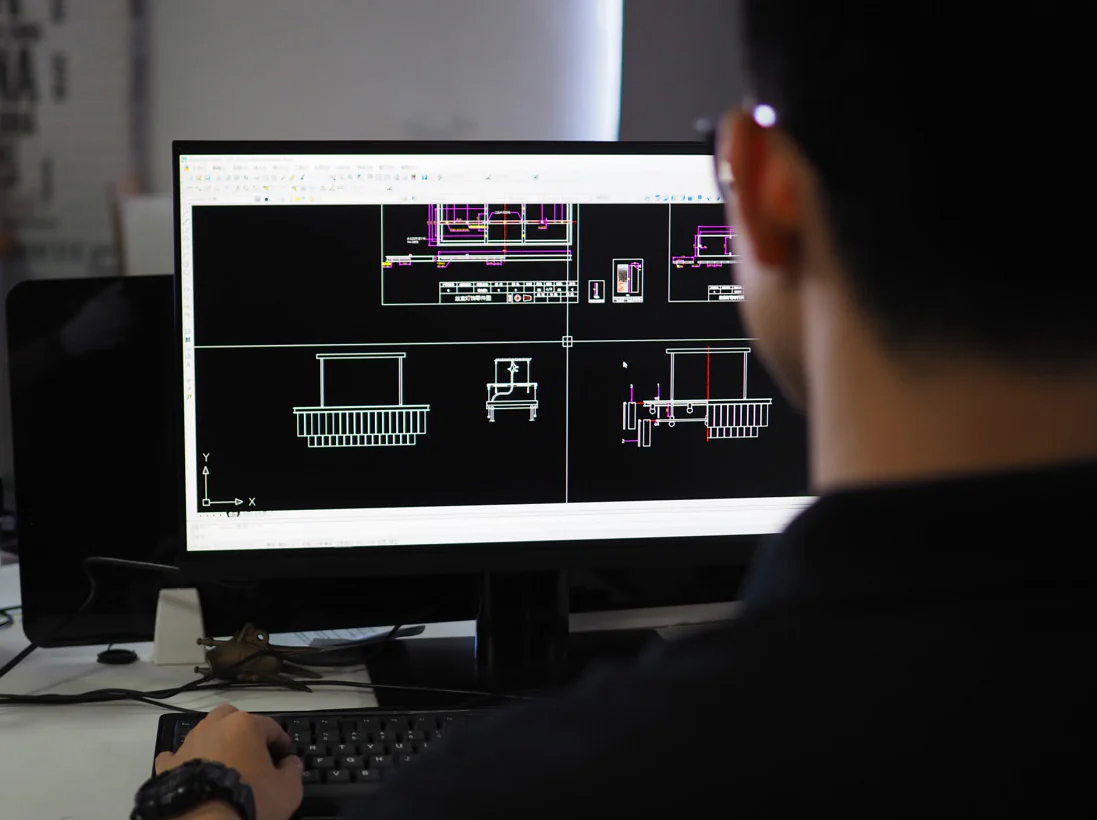

A good product always begins with design. This is a crucial step in the chandelier manufacturing process. All Decca crystal chandeliers are meticulously designed by professionals with years of experience in chandelier design. Our dedicated design team transforms sketches and mockups into practical lighting concepts. From hand-drawn sketches to precise CAD data, the dimensions, shape, and details of each chandelier are meticulously considered by our designers, and our engineers perform micron-level calculations and testing to ensure each product is beautifully designed and flawlessly crafted.

One of our strengths is the flexibility of custom design. We offer personalized services tailored to your unique needs. Choosing us gives you complete control over the look of your chandelier.

Crystal Chandelier Design

Step 2: Base Manufacturing

The base material is crucial to the quality of a chandelier. After the overall chandelier design is completed, we cut and shape the base according to the design drawings. The base is crafted from 1mm high-strength stainless steel and cut into various shapes using a micron-level laser cutting process.

We use a polishing machine to achieve a perfectly smooth surface finish on the steel plate. Each chandelier base is equipped with appropriate ventilation holes to ensure good heat dissipation during long-term use, extending its lifespan.

The chandelier base is responsible for the electrical connections and installation. Once the base is prepared, skilled technicians connect the chandelier wiring and install the hardware. These processes must be strictly controlled and monitored to achieve the desired effect.

All electrical components and wiring in our chandeliers are ETL certified. We use high-quality materials to ensure stability and safety throughout the lifespan of the chandelier. To ensure the lamp is fully functional and energy-efficient, we conduct comprehensive testing. Once the light source components are completed, they undergo 15 quality inspections to ensure safety, stability, and reliability during use.

Manufacturing the Chandelier Base

Step 3: Stringing the Crystals

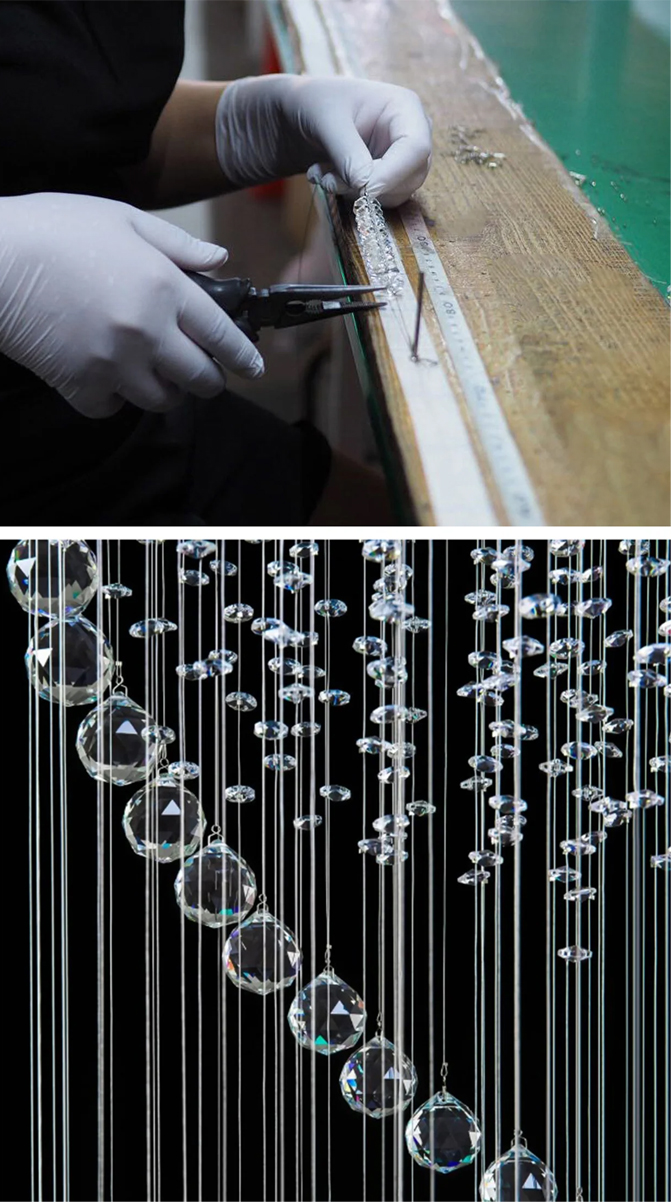

Crystal is the soul of a crystal chandelier. All of our crystal chandeliers are crafted from premium K9 crystal, ensuring they shimmer and dazzle under the light. K9 crystal offers high light transmittance, excellent reflection, high hardness, a delicate texture, and durability, making it an ideal material for high-end chandeliers.

Due to the diverse styles and complex shapes of crystal chandeliers, all crystal strings are handmade. Our employees undergo rigorous pre-training to ensure a flawless production process. Our crystal string production workshop operates in a dust-free environment. After production, the crystal strings are sealed in bags to ensure they arrive spotless upon arrival.

Each handmade crystal string embodies the Deca team's passion for detail, beauty, and creativity.

String the crystals together with the chain.

Step 4: Packaging

Our professional packaging team is responsible for packaging the final product. Once the crystal string is complete, it is paired with the corresponding chandelier base and hardware, and then packaged in a specially designed foam protective box. Before packaging and dispatch, our quality control team conducts a final quality check to ensure the chandelier is in perfect condition.

Good packaging not only ensures safe delivery but also creates a positive first impression. We use high-density foam to protect the crystal ball at all times. Furthermore, the well-designed interior reduces the required packaging size, which is both environmentally friendly and reduces logistics costs. Our goal is always to reduce costs without compromising product quality, which is part of our low-cost management philosophy.

The foam box outer packaging utilizes double-layered, extra-thick corrugated cardboard. This high-strength corrugated cardboard minimizes damage during transportation, ensuring our product arrives intact.

Packaging the Crystal Chandelier

Step 5: Shipping

After packaging, our warehouse staff will label and organize the product for expedited delivery to the freight forwarder, ensuring it reaches our customers as quickly as possible.