Recently, with the rapid development of science and technology, the application of LED technology in the field of lighting and display has become more and more extensive. As the core component of LED technology, the manufacturing process and performance characteristics of LED chips have attracted much attention.

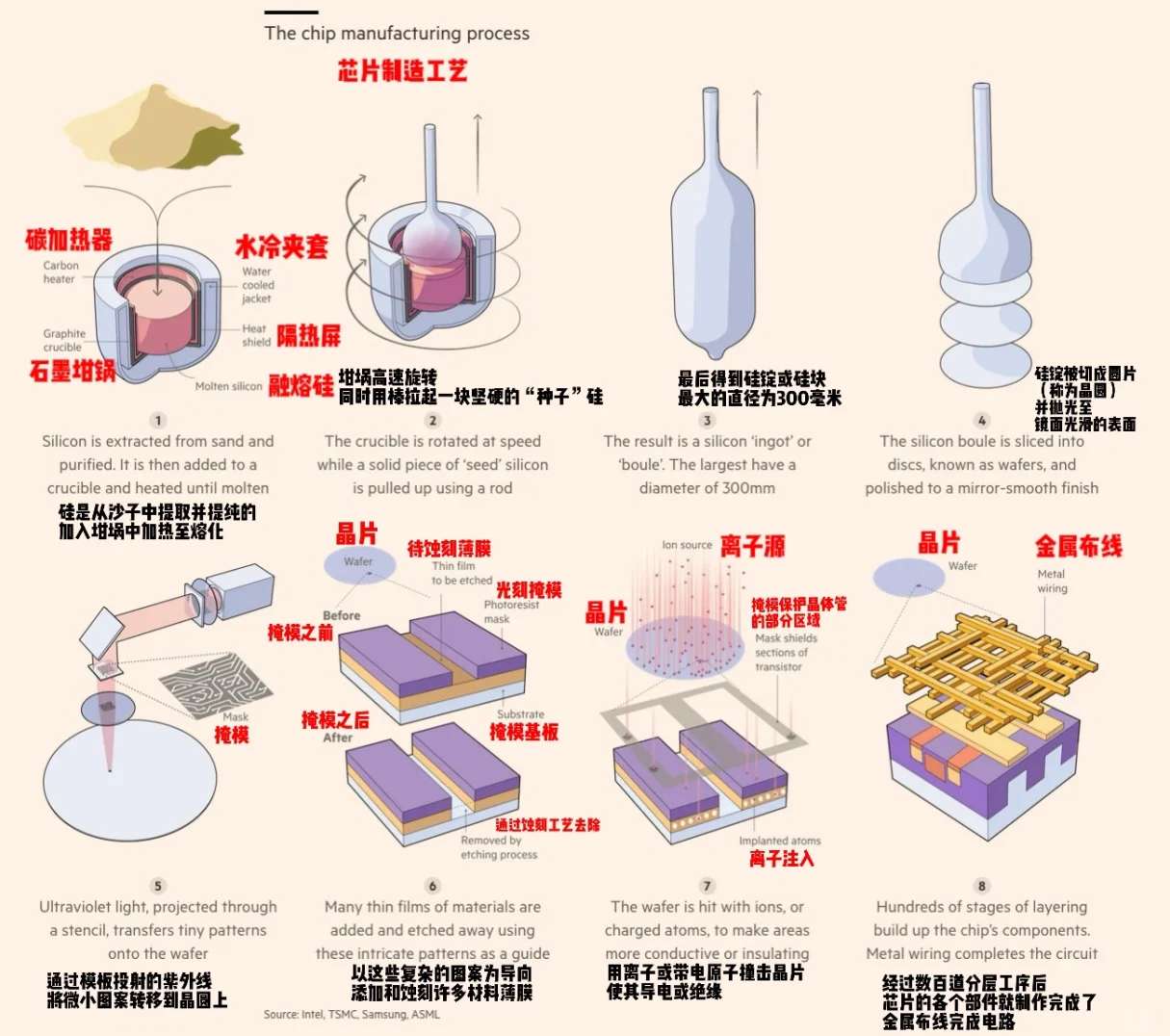

The main goal of LED chip manufacturing is to create an effective and reliable low-ohmic contact electrode, ensure that the voltage drop between the contactable materials is small, and provide a suitable wire bonding pad, while maximizing the light output efficiency. The coating process mostly uses vacuum evaporation. In a high vacuum environment of 4Pa, the material is melted by resistance heating or electron beam bombardment heating. Then, under low pressure, the material becomes metal vapor and is deposited on the surface of the semiconductor material. Usually, AuBe, AuZn and other alloys are used for P-type contact metals, and AuGeNi alloys are often used for N-side contact metals. The alloy layer formed by coating needs to be subjected to a photolithography process to expose as much of the light-emitting area as possible, so that the remaining alloy layer meets the requirements of low-ohmic contact electrodes and wire bonding pads. After the photolithography process is completed, the alloying process is required, which is generally carried out under the protection of H2 or N2. The alloying time and temperature are determined according to factors such as the characteristics of the semiconductor material and the form of the alloying furnace. If the chip electrode process such as blue-green is involved, more complex processes such as passivation film growth and plasma etching need to be added.

In the LED chip manufacturing process, multiple links have a significant impact on its optoelectronic performance. Generally speaking, after the LED epitaxial production is completed, the main electrical properties are basically finalized. Although chip manufacturing will not change its core nature, improper conditions during the coating and alloying process will lead to some poor electrical parameters. For example, if the alloying temperature is too high or too low, it will cause poor ohmic contact, which is the main reason for the high forward voltage drop VF in chip manufacturing. After cutting, the chip edge is corroded to help improve the reverse leakage of the chip. This is because after the diamond grinding wheel blade is cut, a large amount of debris powder will remain on the edge of the chip. If these debris stick to the PN junction of the LED chip, it is easy to cause leakage or even breakdown. In addition, if the photoresist on the chip surface is not stripped cleanly, it will lead to problems such as difficulty in welding wires on the front side and cold welding, and will cause high voltage drop on the back side. In the chip production process, the light intensity can be effectively improved by roughening the surface and dividing it into an inverted trapezoidal structure.

LED chips are divided into low-power, medium-power and high-power chips according to power, and can be divided into single-tube, digital, dot-matrix and decorative lighting categories according to customer needs. The specific size of the chip depends on the actual production level of different chip manufacturers, and there is no unified standard. As long as the process meets the standard, smaller chips can increase unit output and reduce costs, and the optoelectronic performance will not change fundamentally. The chip's operating current is related to the current density flowing through the chip. The smaller the chip, the smaller the operating current, and the larger the chip, the larger the operating current, and the unit current density is basically similar. Considering that heat dissipation is a key issue under high current, the luminous efficiency of high-power chips is lower than that of low current. On the other hand, due to the increase in chip area and the decrease in body resistance, the forward conduction voltage will decrease.

The area of common high-power LED chips used for white light on the market is generally around 40mil. The so-called high-power chip usually refers to an electric power of more than 1W. Since the quantum efficiency is generally less than 20%, most of the electric energy will be converted into heat energy, so the heat dissipation of high-power chips is extremely important, which requires the chip to have a larger area.

The chip process and processing equipment for manufacturing GaN epitaxial materials are significantly different from those of GaP, GaAs, and InGaAlP. The substrates of ordinary LED red and yellow chips and high-brightness four-element red and yellow chips use compound semiconductor materials such as GaP and GaAs. They can generally be made into N-type substrates, which are photolithographically processed by wet processes and finally cut into chips with diamond wheel blades. The blue-green chip of GaN material uses a sapphire substrate. Due to its insulation, it cannot be used as one pole of the LED. It is necessary to make two P/N electrodes on the epitaxial surface at the same time through a dry etching process, and some passivation processes are also required. Because sapphire is hard, it is difficult to cut it into chips with diamond wheel blades, and its process is more complicated than that of LEDs made of GaP and GaAs materials.

"Transparent electrode" chips have unique structures and characteristics. The so-called transparent electrode must have two properties: conductivity and light transmission. At present, indium tin oxide (ITO) is widely used in the liquid crystal production process, but it cannot be used as a solder pad. When making it, you need to first make an ohmic electrode on the surface of the chip, then cover it with a layer of ITO, and then plate a solder pad on the surface of the ITO. In this way, the current coming down from the lead can be evenly distributed to each ohmic contact electrode through the ITO layer. At the same time, the refractive index of ITO is between the refractive index of air and epitaxial material, which can increase the light output angle and increase the luminous flux.

With the development of semiconductor LED technology, the application of lighting, especially white light LED, has become a hot spot, but the key chip and packaging technology still needs to be improved. In terms of chips, the future will be towards high power, high light efficiency and reduced thermal resistance. Increasing power means increasing the current used by the chip. The most direct way is to increase the chip size. The size of the currently common high-power chip is about 1mm×1mm, and the current used is about 350mA. Due to the increase in the current used, the heat dissipation problem has become more prominent. Now the chip flip method has basically solved this problem.

Blue LEDs often use Al2O3 substrates, which have high hardness and low thermal and electrical conductivity. If a positive structure is used, not only will there be anti-static problems, but heat dissipation will also become a major problem under high current conditions. At the same time, since the front electrode faces upward, it will block part of the light and reduce the luminous efficiency. High-power blue LEDs can obtain more effective light output through chip flip-chip technology compared to traditional packaging technology. The mainstream flip-chip structure manufacturing process is: first prepare a large-size blue LED chip with electrodes suitable for eutectic welding, and at the same time prepare a silicon substrate slightly larger than the blue LED chip, and make a gold conductive layer and lead wire layer (ultrasonic gold wire ball solder joint) for eutectic welding on it. Then, use eutectic welding equipment to weld the high-power blue LED chip to the silicon substrate. In this structure, the epitaxial layer is directly in contact with the silicon substrate, and the thermal resistance of the silicon substrate is much lower than that of the sapphire substrate, which effectively solves the heat dissipation problem. After flipping, the sapphire substrate faces upward to become the light-emitting surface. Due to its transparency, the light-emitting problem is also solved.

Industry experts said that with the continuous advancement of science and technology, LED chip technology will continue to innovate, and future LED lamps are expected to make greater breakthroughs in high efficiency and long life, bringing more convenience to people's lives.