Scientists at King Abdullah University of Science and Technology (KAUST) and King Abdulaziz City for Science and Technology (KACST) in Saudi Arabia have developed an innovative nano-coating technology that can significantly improve the energy efficiency of LED streetlights and reduce carbon emissions, which is of great significance to the lighting industry.

The study, published in the journal Light: Science & Applications, shows that if applied in the United States alone, it can reduce more than 1.3 million tons of carbon dioxide emissions each year, which has a positive driving effect on the improvement of global lighting energy consumption.

(Lighting) is a huge source of energy consumption, accounting for about 20% of the world's total electricity consumption and nearly 6% of greenhouse gas emissions. Street (lighting) also accounts for 1-3% of global electricity demand, which puts a burden on municipal units. Although LEDs are efficient light sources, about 75% of the energy is converted into heat energy when working, which has a negative impact on the (lighting) effect and lamp life. High temperatures not only reduce the (lighting) luminous efficiency, but also shorten the life of the lamp. Therefore, effective thermal management is crucial to improve LED (lighting) performance.

The key to the research team's development is a nanomaterial called nanoPE (nanoporous polyethylene). This material is made of ordinary polyethylene, and a special process is used to make holes of only 30 nanometers (about one thousandth of a hair). Its uniqueness is that it allows infrared light (the main source of thermal radiation) to penetrate efficiently (more than 80%), while reflecting visible light efficiently (more than 95%), making it possible to optimize the (lighting) effect.

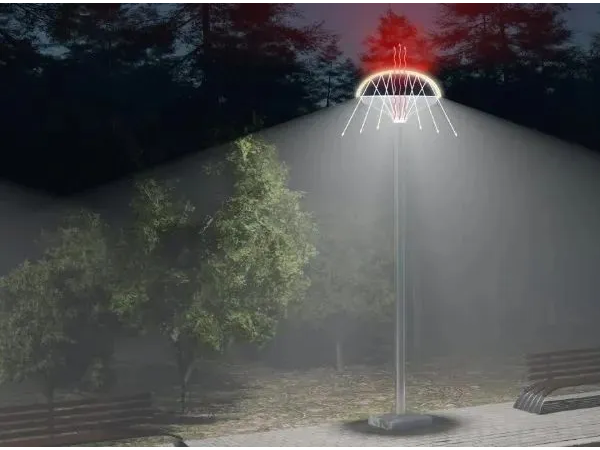

In order to maximize the effectiveness of nanoPE, the researchers proposed to install LED street lights coated with this material "upside down". In this way, the heat energy (infrared light) generated by the lamp can smoothly penetrate nanoPE and radiate upward to the sky to dissipate, while the visible light required for downward (lighting) is effectively reflected to the ground. This is completely different from the design of traditional LEDs that trap heat energy inside and the lamp head is facing down, and it is an innovative breakthrough in (lighting) technology.

The experimental results confirmed that after applying the nano-polyethylene coating, the temperature of the LED was reduced by 7.8°C in laboratory conditions and 4.4°C in outdoor measurements, and the (lighting) efficiency was increased by about 5% and 4%, respectively. Professor Qiao Qiang, the leader of the study, emphasized that even a small improvement in (lighting) efficiency can have a huge impact on sustainable development when applied on a large scale. Co-author Dr. Hussam Qasem also believes that this design significantly improves heat dissipation while maintaining high (lighting) efficiency, and is a potential solution for sustainable (lighting), which is expected to be widely used in the (lighting) field in the future.