In the modern development of the lighting industry, LED and COB light sources are undoubtedly the two most dazzling pearls. They rely on their unique technical advantages to jointly promote the progress of the industry. This article will deeply analyze the differences and advantages and disadvantages of COB light sources and LEDs, and explore the opportunities and challenges faced by the two in the current lighting market environment, as well as the impact on the future development trend of the industry.

PART.01

Packaging process: the leap from discrete units to integrated modules

Traditional LED light sources

Traditional LED light sources adopt a single-chip packaging mode, which consists of LED chips, gold wires, brackets, phosphors and packaging colloids. The chip is fixed to the bottom of the reflector cup bracket by conductive glue, the gold wire connects the chip electrode and the bracket pin, and the phosphor is mixed with silica gel to cover the chip surface to achieve spectral conversion. This packaging method creates a variety of forms such as direct plug-in and patch type, but it is essentially a repeated combination of independent light-emitting units, like scattered pearls, which need to be carefully connected in series to shine. However, when constructing a large-area light source, the complexity of the optical system will increase exponentially, just like building a magnificent building, which requires a lot of manpower and material resources to splice and combine each brick and stone.

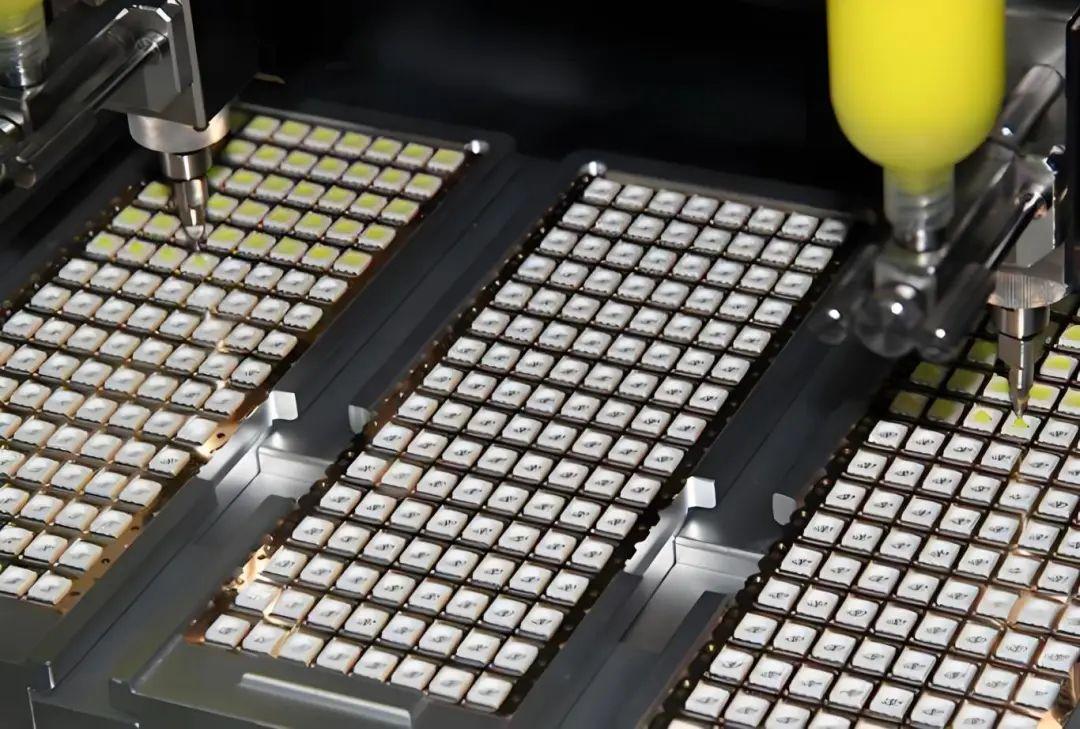

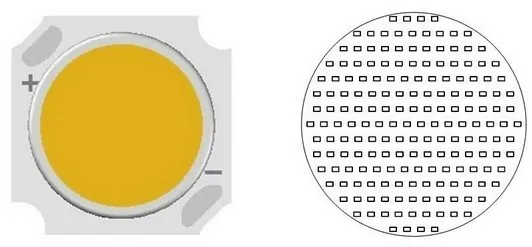

COB light source

COB light source breaks through the traditional packaging paradigm and adopts multi-chip direct welding technology to directly bond dozens to thousands of LED chips on a metal-based printed circuit board or ceramic substrate. The chips are electrically interconnected through high-density wiring, and the entire surface is covered with a silicone layer containing phosphor to form a uniform luminous surface. This architecture is like inlaying pearls on a beautiful canvas, eliminating the physical gap between single LEDs and realizing the collaborative design of optics and thermals. For example, Lumileds LUXEON COB uses eutectic welding technology to integrate 121 0.5W chips on a circular substrate with a diameter of 19mm, with a total power of 60W. The chip spacing is compressed to 0.3mm. With a special reflective cavity, the uniformity of light distribution exceeds 90%. This integrated package not only simplifies the production process, but also creates a new form of "light source as module", providing a revolutionary foundation for lamp design, just like providing lighting designers with exquisite prefabricated modules, greatly improving the efficiency of design and production.

PART.02

Optical properties: the transformation from point light source to surface light source

Single LED

A single LED is essentially a Lambertian light source with a light-emitting angle of about 120°, but the light intensity distribution is a bat-wing curve with a sharp decrease in the center, like a bright star, shining but somewhat scattered. In order to meet the lighting needs, the light distribution curve needs to be reshaped through secondary optical design. The lens system uses TIR lens to compress the light-emitting angle to 30°, but the light efficiency loss is 15%-20%; the parabolic reflector in the reflector solution can increase the central light intensity, but it will produce obvious light spots; when multiple LEDs are combined, they need to maintain sufficient spacing to avoid chromatic aberration, which will increase the thickness of the lamp, just like trying to piece together a perfect picture with stars in the night sky, but it is always difficult to avoid flaws and shadows.

Integrated architecture COB

COB's integrated architecture naturally has the characteristics of a surface light source, like a brilliant galaxy, with uniform and soft light. The dense arrangement of multiple chips eliminates dark areas, and with the microlens array technology, the illumination uniformity can be >85% within a distance of 5m; through the roughening of the substrate surface, the light angle can be expanded to 180°, reducing the glare index (UGR) to below 19; under the same luminous flux, the optical extension of COB is 40% lower than that of the LED array, which significantly simplifies the lighting design. In the museum lighting scene, ERCO's COB track light achieves an illumination ratio of 50:1 at a projection distance of 0.5 meters through a free-form lens, which perfectly solves the contradiction between uniform illumination of the product and highlighting the key points.

PART.03

Thermal management solution: innovation from local heat dissipation to system-level heat conduction

Traditional LED light source

Traditional LED adopts a four-level heat conduction path of "chip - solid crystal layer - bracket - PCB", and the thermal resistance is complex, like a winding path, which hinders the rapid dissipation of heat. In terms of interface thermal resistance, there is a contact thermal resistance of 0.5-1.0℃/W between the chip and the bracket; in terms of material thermal resistance, the thermal conductivity of FR-4 board is only 0.3W/m·K, which becomes a heat dissipation bottleneck; under the cumulative effect, local hot spots can increase the junction temperature by 20-30℃ when multiple LEDs are combined. Experimental data show that when the ambient temperature reaches 50℃, the light decay rate of SMD LED is 3 times faster than that of 25℃ environment, and the life is shortened to 60% of the L70 standard, just like being exposed to the sun for a long time, the performance and life of LED light sources will be greatly reduced.

COB light source

COB adopts a three-level conduction architecture of "chip - substrate - heat sink" to achieve a qualitative leap in thermal management, just like paving a wide and flat highway for the light source, allowing heat to be quickly conducted and dissipated. In terms of substrate innovation, the thermal conductivity of the aluminum substrate reaches 2.0W/m·K, and the aluminum nitride ceramic substrate reaches 180W/m·K; in terms of heat dissipation design, a heat dissipation layer is laid under the chip array to control the temperature difference within ±2℃; at the same time, it is compatible with liquid cooling, and the heat dissipation capacity reaches 100W/cm² after the substrate contacts the liquid cooling plate. In the application of automotive headlights, Osram COB light sources use thermoelectric separation design to stabilize the junction temperature below 85℃, meet the AEC-Q102 automotive-grade reliability requirements, and have a lifespan of over 50,000 hours, just like when the car is driving at high speed, it can still provide drivers with stable and reliable lighting to ensure driving safety.

PART.04

Light efficiency and energy efficiency: a breakthrough from theoretical limits to engineering optimization

Traditional LED light sources

LED light efficiency improvement follows Heitz's law and continues to break through through material system and structural innovation. In epitaxial optimization, InGaN/GaN multi-quantum well structure makes the internal quantum efficiency reach 90%; patterned substrates such as PSS patterns increase the light extraction efficiency to 85%; in terms of phosphor innovation, the combination of CASN red powder and LuAG yellow-green powder achieves a color rendering index of Ra>95. Cree's KH series LED has a light efficiency of 303lm/W, but the transformation of laboratory data to engineering applications still faces practical challenges such as packaging loss and driving efficiency, just like a gifted athlete who can create amazing results in an ideal state, but in the actual arena, it is subject to various factors.

COB light source

COB achieves breakthroughs in engineering light efficiency through the synergy of optical coupling and thermal management. When the chip spacing is <0.5mm, the optical coupling loss is <5%; the light attenuation rate decreases by 50% for every 10℃ decrease in junction temperature; the integrated driver design enables the AC-DC driver to be directly integrated into the substrate, and the system efficiency reaches 90%. In agricultural lighting applications, Samsung LM301B COB achieves PPF/W (photosynthetic photon efficiency) of 3.1μmol/J through spectrum optimization and thermal management, which is 40% energy-saving compared with traditional HPS lamps. Like an experienced craftsman, through careful adjustment and optimization, the light source can play the maximum efficiency in practical applications.

PART.05

Application scenarios: From differentiated positioning to the expansion of integrated innovation

Traditional LED light sources

LEDs occupy specific markets with their flexibility. In the field of indication display, 0402/0603 packaged LEDs dominate the consumer electronics indicator light market; in special lighting, UV LEDs have formed a monopoly in the curing and medical fields; in dynamic display, Mini LED backlights achieve a contrast ratio of 10000:1, subverting LCD displays. For example, in the field of smart wearables, Epistar's 0201 red LED is only 0.25mm² in size, but can provide 100mcd of light intensity, meeting the needs of heart rate monitoring sensors.

COB light source

COB is redefining the paradigm of lighting engineering. In commercial lighting, a certain brand of COB downlight achieves a system light efficiency of 120lm/W, which is 60% energy-saving compared with traditional solutions; in outdoor lighting, most domestic COB street light brands can already achieve on-demand lighting and light pollution control through intelligent dimming; in emerging application areas, UVC COB light sources achieve a 99.9% sterilization rate in the field of water treatment, and the response time is <1 second. In the field of plant factories, through the optimization of the spectrum formula of COB full-spectrum light sources, the vitamin C content of lettuce can be increased by 30% and the growth cycle can be shortened by 20%.

PART.06

Opportunities and Challenges: Ups and Downs in the Market Wave

Opportunities

Consumption Upgrading and Quality Demand Improvement: With the improvement of living standards, people's requirements for lighting quality have increased. COB has ushered in a broad market in high-end residential lighting and commercial lighting with its excellent luminous performance and uniform light distribution; LED is favored in the smart lighting and atmosphere lighting markets with its rich colors and flexible dimming and color adjustment functions, which meets the consumer's demand for personalized and intelligent lighting products under the trend of consumption upgrading.

Energy-saving and environmental protection policy promotion: The world attaches great importance to energy conservation and environmental protection, and governments of various countries have introduced policies to encourage the lighting industry to develop in the direction of high efficiency and energy saving. As a representative of energy-saving lighting, LED has low energy consumption and long life, which enables it to obtain a large number of market application opportunities under policy support. It is widely used in indoor and outdoor lighting, road lighting, industrial lighting and other fields; COB also benefits. While improving the quality of lighting, it can achieve certain energy-saving effects. In professional lighting scenes with high light utilization requirements, it can improve energy-saving effects through optical design and energy conversion.

Technological innovation and industrial upgrading: The wave of technological innovation in the lighting industry continues, providing new impetus for the development of COB and LED. COB R&D personnel explore packaging materials and processes to improve its heat dissipation performance, light efficiency and reliability, reduce production costs, and expand the scope of application; LED chip technology breakthroughs, packaging form innovations, and intelligent control technology integration have greatly improved its performance and functions.

Challenges

Fierce market competition: COB and LED are facing fierce competition from many manufacturers. The LED market has mature technology, low entry barriers, serious product homogeneity, fierce price competition, and compressed corporate profit margins; although COB has advantages in the high-end market, as the number of companies increases, competition has also intensified, and creating differentiated competitive advantages has become a challenge for companies.

Fast technology updates: The lighting industry has a fast technology update, and COB and LED companies need to keep up with the pace of technological development and adapt to market changes and consumer demand. COB companies need to pay attention to the progress of chips, packaging processes, and heat dissipation technologies, and adjust the direction of product development; LED companies face the dual pressure of traditional technology upgrades and the rise of new lighting technologies.

Imperfect standards and specifications: The industry standards and specifications of COB and LED are imperfect, and there are gray areas in product quality, performance testing, safety certification, etc., resulting in uneven product quality, making it difficult for consumers to judge the quality, bringing difficulties to corporate brand building and market promotion, and increasing corporate operating risks and costs.

PART.07

Industry development trends: The future path of integration, high-end and diversification

Fusion development trends: COB and LED are expected to achieve integrated development. For example, in lighting products, COB, as the main light source, provides uniform and high-brightness basic lighting, combined with the color adjustment and intelligent control functions of LED, to achieve diversified and personalized lighting effects, give full play to the advantages of both, and meet the comprehensive and in-depth needs of consumers.

High-end and intelligent development go hand in hand: With the improvement of quality of life and lighting experience requirements, COB and LED are developing in the direction of high-end and intelligent. Enterprises will increase investment in R&D and innovation, improve product performance, quality and design, and create a high-end brand image; lighting products will be integrated with technologies such as the Internet of Things, big data, and artificial intelligence to achieve functions such as automated control, scene switching, and energy consumption monitoring. Consumers can remotely control lighting equipment through mobile phone APP or smart voice assistants to achieve energy-saving management.

Diversified application expansion: COB and LED application areas continue to expand and diversify. In addition to traditional indoor and outdoor lighting, road lighting and other markets, they will also play an important role in emerging fields such as agricultural lighting, medical lighting, and marine lighting. For example, LEDs in agricultural lighting emit light of a specific wavelength to promote plant photosynthesis; the high color rendering and uniform light of COB in medical lighting help doctors diagnose and treat and improve the medical environment for patients.

In the vast starry sky of the lighting industry, COB light sources and LED light sources will continue to shine, each playing their own advantages, and integrating innovation with each other to jointly illuminate the bright road of sustainable development for mankind. They are like a pair of explorers walking side by side, constantly exploring new shores in the ocean of technology, bringing more surprises and light to people's lives and the development of all walks of life.