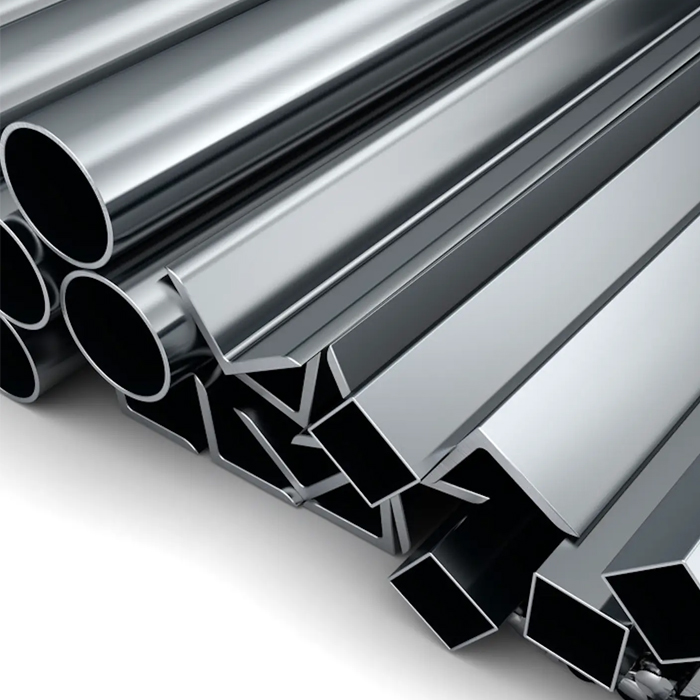

Aluminum alloy

Aluminum alloy is the most widely used basic material in the production of lamps. The core purpose of the lamp "mold opening" (i.e. die-casting mold production) we often say is to prepare for the aluminum alloy die-casting process. The newly purchased aluminum alloy raw materials are usually in the form of aluminum ingots. After being processed by a die-casting machine, they can form various core structural parts of the lamp, such as the heat dissipation lamp body and face ring on the back of the lamp, and the overall lamp body formed by direct die-casting. Aluminum alloy has become the preferred material for many lamp products due to its advantages of light weight, high strength and convenient processing.

Zinc Alloy

Compared with aluminum alloy, zinc alloy has a lower cost, so it is often used in lamp parts with low material performance requirements. It is slightly heavier than aluminum alloy, but has obvious price advantages, so it is widely used in mid-range lamp products, especially suitable for making small spare parts.

Steel

Steel is also a common material in lamp manufacturing, and its application scenarios are very wide. The price of steel is much lower than that of aluminum, and it has good plasticity. Therefore, those die-cast parts with high strength requirements but low precision requirements are usually made of steel plates. For example, the overall lamp body structure on the upper part of the lamp panel is mostly processed by steel plate bending technology.

Plastic

Plastic is a general term for a class of high molecular polymers, including PC, PMMA and other specific types. Its raw material is rice-like colloidal particles. After being injected into the corresponding mold by an injection molding machine, lampshades, covers, shells and other parts of various colors can be pressed out. Black plastic is widely used in lamps and can be used to make parts, covers, panels, etc. Some lamps even use all-plastic structures; while colored plastics are relatively rarely used in lamps.

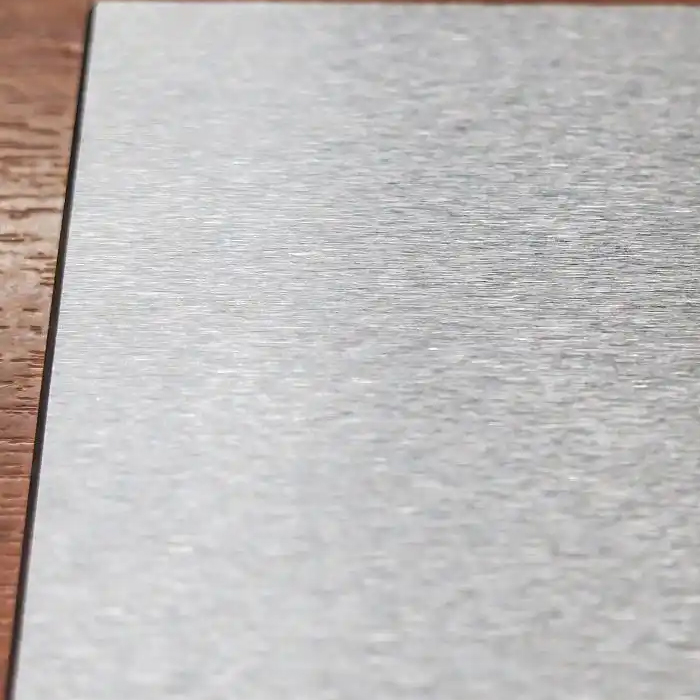

Mirror aluminum

Mirror aluminum is a material unique to the lighting industry and is rarely used in other fields. This aluminum plate has a smooth surface like a mirror and has excellent light reflection performance. Therefore, it is specially used to make reflectors for lamps. Reflective parts in lamp panels and reflective structures in LED tube spotlights are often made of mirror aluminum.

Sand-faced aluminum

In addition to smooth mirror aluminum plates, coarse sand aluminum plates are also widely used in lamps. The roughness of the sanded aluminum plate can be divided into two types: light sand and heavy sand. It is also used as a reflector, but the light control accuracy is not as good as that of the mirrored aluminum plate. The significant feature of the sanded aluminum plate is that when light hits its surface, it will be diffusely reflected in all directions. Therefore, in scenes that require diffuse light effects but do not require precise light control, the sanded aluminum plate is an ideal choice.