Preventing LEDs from corroding is an important part of improving LED reliability. This article analyzes the reasons why LEDs corrode and gives the main methods to avoid corrosion - preventing LEDs from approaching harmful substances and effectively limiting the concentration level of harmful substances and ambient temperature.

Q: How to prevent LEDs from corroding?

Keywords: LED, corrosion, product performance, optoelectronic components

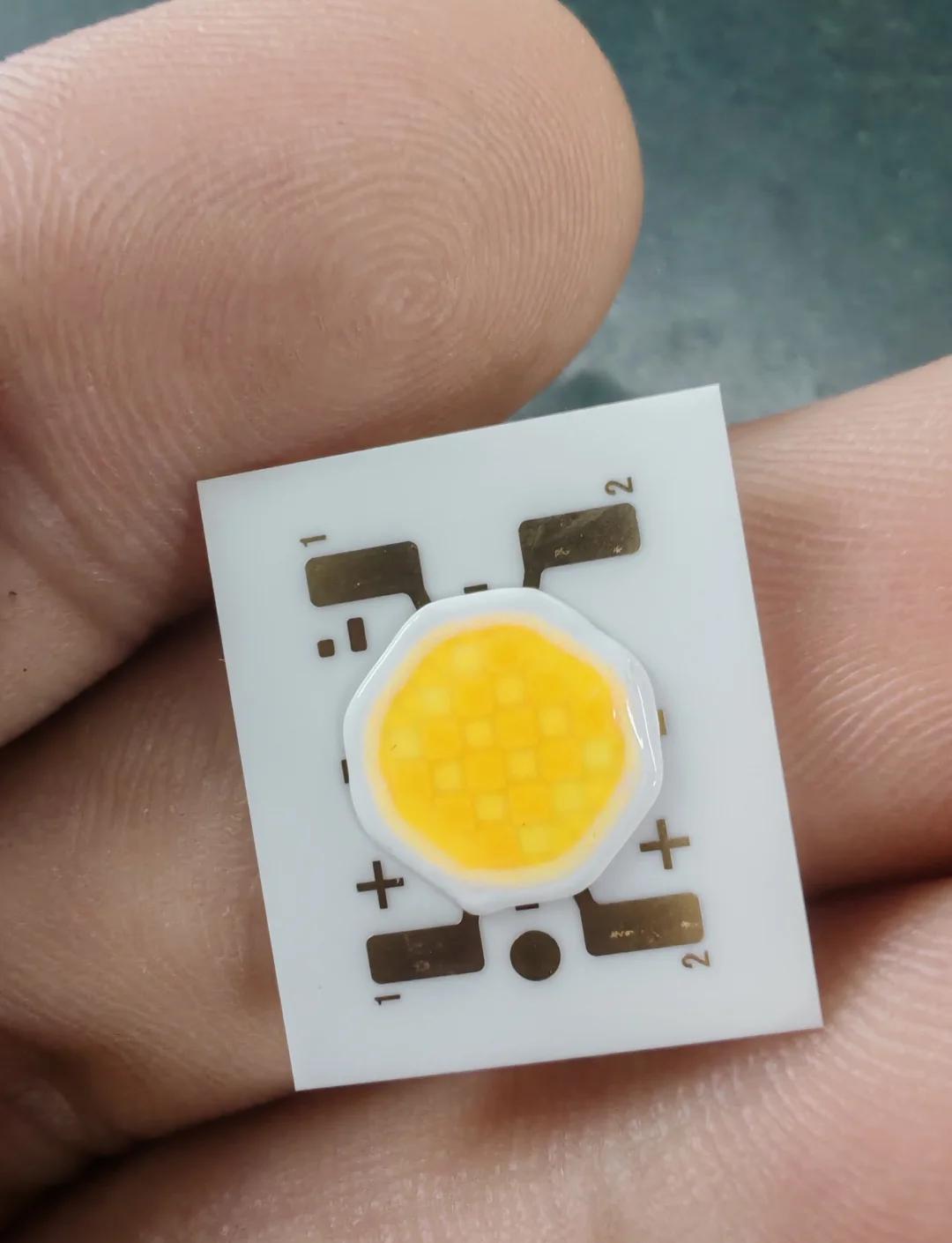

The reliability of LED products is one of the important specifications used to estimate the life of LED products. Even under most different conditions, general LED products can continue to operate. However, once the LED is corroded, the LED will react chemically with the surrounding environment, which will reduce the performance of the LED product.

To prevent LEDs from corroding, the best way is to prevent LEDs from approaching harmful substances. Even a small amount of harmful substances can cause LED corrosion. Even if the LED is only in contact with corrosive gases during processing, such as machines in a production line, it may have adverse effects. In these cases, it is usually possible to observe whether the LED components are damaged before the actual system is set up. Sulfur contamination should be avoided in particular.

Here are some examples of materials that may contain corrosive substances (especially hydrogen sulfide):

O-rings

Gaskets

Organic rubber

Foam pads

Sealing rubber

Sulfur-containing vulcanized elastomers

Anti-vibration pads

If these harmful substances cannot be completely avoided, LEDs with higher corrosion resistance should be used. However, please remember that the effect of limiting corrosion depends on the concentration of harmful substances. Even if you choose a more durable LED, you should try to minimize the exposure of these LED materials.

Generally, heat, humidity and light can accelerate the corrosion process. However, the main influencing factors are the concentration level and temperature of harmful substances. Limiting these two will be an important way to protect LEDs.

In production scenarios with corrosive media such as petroleum, chemical industry, metallurgy, and light industry, special anti-corrosion lamps are required. In addition to meeting basic anti-corrosion standards, such lamps must also pass professional tests such as chemical gas corrosion tests, wet and hot environment tests, and shell protection performance tests to fully ensure their operational reliability under complex and harsh working conditions.